R3-PowerUP

300mm Pilot Line for Smart Power and Power Discretes

|

R3-PowerUP 300mm Pilot Line for Smart Power and Power Discretes |

|

R3-POWERUP will push through the new generation of 300mm Pilot Line Facility for Smart Power microelectronic technology in Europe. This will enable the European industry to set the world reference of innovative and competitive solutions for critical societal challenges, like Energy saving and CO2 Reduction (ref. to COP21 Agreement1), as well as Sustainable Environment through electric mobility and industrial power efficiency.

The R3-POWERUP project builds on the precursor project R2POWER300 (ECSEL 2014) that can be considered as the preparatory study to the big leap from 200mm to 300mm fab.

The overall concept of R3-POWERUP is the setup of the 300mm Pilot Line for Smart Power devices that will allow:

the development of more advanced Smart Power technology generations calling for <100nm lithography; only new generation tools, available at 300mm, can indeed guarantee the adequate process features and control (in terms of uniformity, repeatability, defect and contamination control) needed for manufacturing of Smart Power technological nodes below 100nm lithography; the development of critical process steps of power discrete devices (i.e. IGBT and vertical power MOS) at 300mm and the investigation of the compatibility/sinergy with Smart Power processing in the same line;

the validation of the Smart Power process through the Final Demonstrators, developed with the key application and technology partners, covering all aspects from device technology to application vehicles and 3D packaging; the validation of the economic feasibility of 300mm processing for Smart Power and Power discrete devices, in view of the future extension to 300mm full production scale.

As such, the project is truly multi-disciplinary:

The project will exploit very relevant application driven solutions for Automotive, Smart Energy, renewable and industrial control domains through the Final Demonstrators.

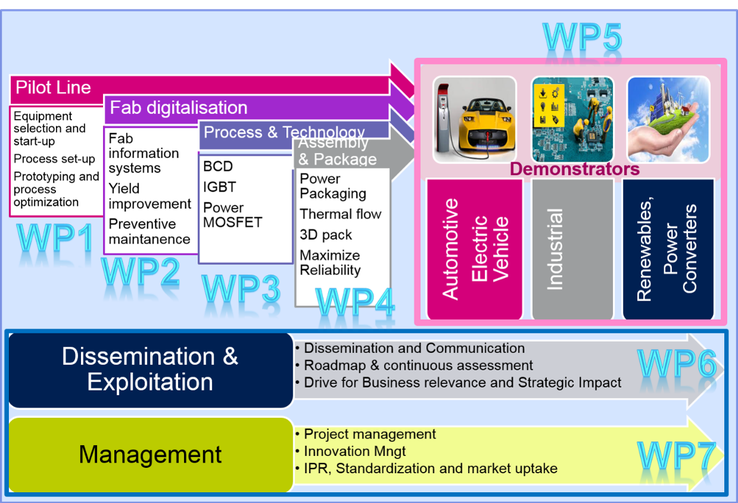

R3-POWERUP’s work plan is made by seven work packages, as depicted in the diagram below. The five main technical work packages are structured as a consistent supply chain for the whole work stream, from Pilot Line set-up and equipment selection to Fab Digitalization, Technology development, Packaging and 3D Modules, down to Demonstrators design and validation. The two horizontal Work Packages are respectively dedicated to the dissemination, exploitation and standardization of results and to project Management.

WP1 Manufacturing Pilot Line

To set-up a qualified and reliable 300mm Pilot Line for Smart Power and Power Discretes technology, including equipment selection, installation and validation.

WP2 Fab digitalisation, yield improve and management

To implement a dedicated Manufacturing Execution System for the 300mm line, based on existing solution and able to support full production in the follow-up of the project. To organize data collection from equipment, in-line metrology and end-of-process testing and develop data analysis tools for process optimization and yield improvement.

WP3 Technology research and development

To develop the advanced 90nm Smart Power technology, including also technology options required by application partners, and to implement it in the 300mm Pilot Line. To validate in the Pilot Line the key manufacturing process steps for power discrete devices.

WP4 Assembly, Packaging and 3D integration

Design of Intelligent Power Modules, innovative 3D structures and materials, advanced solutions for packaging of power devices, including wafer thinning, special bonding and contact options, enhanced thermal management, modelling and reliability.

WP5 Demonstrators

To design and process technology demonstrators to be processed in the 300mm Pilot Line, based on the contribution of application partners. Demonstrators are expected to address several domains: Automotive, electric mobility, renewable energy, power converters industrial control, domotics new solutions of peculiar 300mm equipment, Industry 4.0 Fab automatization, advanced power packaging.

WP6 Dissemination, exploitation, standardization and communication

To take care of the dissemination/communication and of the industrial exploitation of project’s results, taking into account also possible synergies with other European projects in similar areas. To consider constraints coming from existing and emerging standards, and to boost possible standardization initiatives triggered by the project.

WP7 Project Management, Innovation and IPR

To take care of the administrative and technical management of the project, in order to meet the project objectives within the scheduled time. To officially interface the JU and the EC. To manage the users’ access to the Pilot Line, ensuring the protection of IP rights and leveraging their value.